Grassl Group

Concrete Mechanics for Performance Based Design

LS-DYNA examples for using CDPM2 (Student projects)

Below are example LS-DYNA analyses using CDPM2 (Concrete Damage–Plasticity Model 2) for MSc and undergraduate projects. For general setup guidance, see the Info for student projects.

Quick start

Download the ready-to-use package (mesh template, material/control examples, simple Perl tools):

- Generate mesh with T3D

- Convert T3D mesh to LS-DYNA keywords

- Run LS-DYNA (example: 8 cores)

t3d -d 0.02 -p 8 -i mesh.in -o mesh.out

perl t3d2lsdyna.pl mesh.out > mesh.k

lsdyna i=input.k ncpu=8 > std.out &

Visualise: open d3plot in LS-PrePost. For curves, use the included Perl scripts (e.g., reaction.pl).

Outline

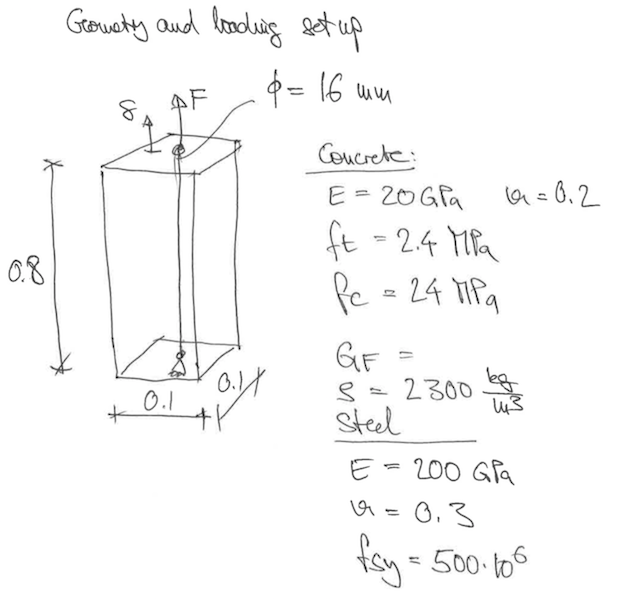

Example: Reinforced concrete prism subjected to tension (LS-DYNA)

We demonstrate the LS-DYNA pipeline on a prism with a single central rebar tensioned through the bar.

Discrete reinforcement is modelled with beam/truss elements. Typical options:

- (a) rebar constrained in the solid mesh,

- (b) shared nodes between rebar and solid,

- (c) coincident nodes with slip (see DOI; inputs linked from LS-DYNA page).

Pipeline

- Generate mesh with T3D

- Convert T3D output to LS-DYNA format

- Create control and material files; adjust

mesh.kin LS-PrePost - Run LS-DYNA

- Postprocess with LS-PrePost and Perl scripts

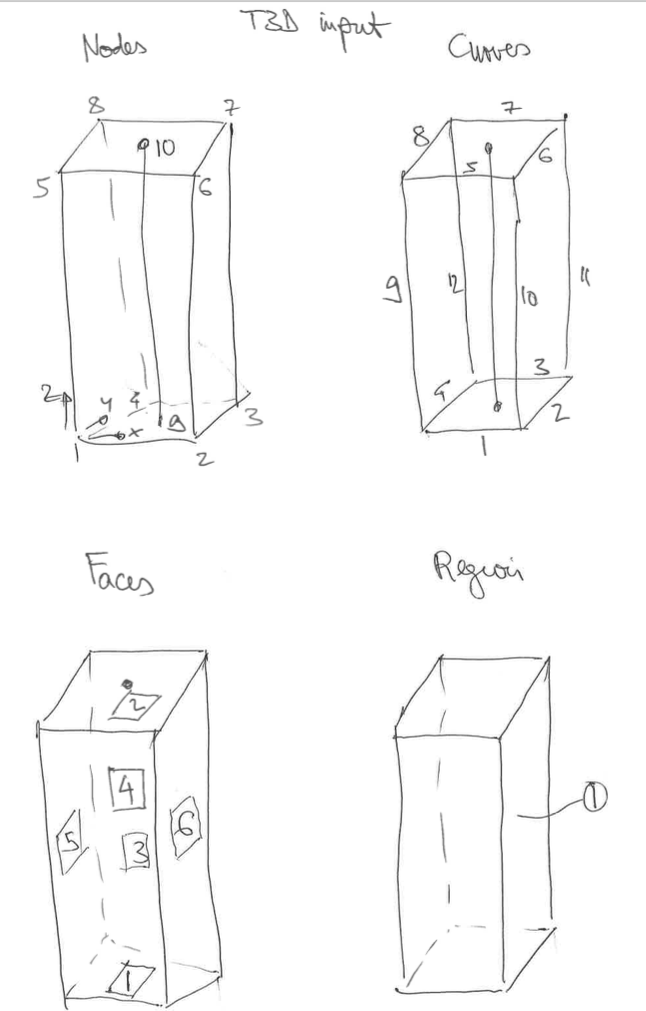

1) Generate mesh with T3D

We use T3D because it creates robust tetra meshes and supports rebar options. Constant-strain tets are suitable for localisation in nonlinear fracture analyses.

Typical command:

t3d -d 0.02 -p 8 -i mesh.in -o mesh.out

Central rebar (curve 13) written to output (option a/b)

curve 13 order 2 vertex 9 10 output yes

Faces (patches)

# bottom / top / front / back / left / right patch 1 normal 0 0 1 boundary curve 1 2 3 4 patch 2 normal 0 0 1 boundary curve 5 6 7 8 patch 3 normal 0 -1 0 boundary curve 1 10 -5 -9 patch 4 normal 0 -1 0 boundary curve -3 11 7 -12 patch 5 normal 1 0 0 boundary curve -4 12 8 -9 patch 6 normal 1 0 0 boundary curve 2 11 -6 -10

Region

region 1 boundary patch -1 2 3 -4 -5 6 size def

For shared nodes (option b), “fix” the rebar vertices in the faces and region:

# patches containing control vertices patch 1 normal 0 0 1 boundary curve 1 2 3 4 fixed vertex 9 patch 2 normal 0 0 1 boundary curve 5 6 7 8 fixed vertex 10 # region includes rebar curve as fixed region 1 boundary patch -1 2 3 -4 -5 6 size def fixed curve 13

Interactive meshing (if T3D built with X11):

t3d -X -d 0.02 -p 8 -i mesh.in -o mesh.out

2) Convert to LS-DYNA format

Minimal converter usage:

perl t3d2lsdyna.pl mesh.out > mesh.k

The script reads node/element blocks from mesh.out and writes LS-DYNA *NODE/*ELEMENT blocks to mesh.k.

3) Control & material files; LS-PrePost adjustments

Keep three files per model:

input.k— analysis controls, includes, BCs, loadsmaterial.k— material cards (concrete & steel)mesh.k— nodes/elements/sets (edit this one with LS-PrePost only)

In LS-PrePost, create node sets (e.g., the nodes at vertices 9 and 10) and a beam set for the rebar. See your internal tutorial for creating sets.

CDPM2 material via user model (abridged):

*MAT_USER_DEFINED_MATERIAL_MODELS

$# mid ro mt lmc nhv iortho ibulk ig

1 2.30E3 50 26 27 0 25 26

$# ivect ifail itherm ihyper ieos lmca

1 0 0 0 0 0

$ p1(E) p2(PR) ... p5(FT) p6(FC) p7(HP)

20.e9 0.2 2.4e6 24.e6 0.01

$ p17(WF) ... p22(EFC)

103.7e-6 1.0e-3

Steel (rebar) — bilinear plasticity:

*MAT_PLASTIC_KINEMATIC

$# mid ro e pr sigy etan beta

2 7.85E3 200.E9 0.3 500.E6 0. 0.0

Parts and sections:

*PART

solid

$# pid secid mid

1 1 1

*PART

reinforcement

$# pid secid mid

2 2 2

*SECTION_SOLID

$ secid elform

1 10 $ constant-strain tets

*SECTION_BEAM_TITLE

Section reinforcement

$ secid elform shrf qr/irid cst

2 1 1.0 2 1

Embed discrete rebar into solid (option a):

*CONSTRAINED_BEAM_IN_SOLID

$ slave master sstyp mstyp

2 1 1 1

Includes:

*INCLUDE material.k *INCLUDE mesh.k

BCs and prescribed displacement:

*BOUNDARY_SPC_SET $ ID CID DOFX DOFY DOFZ DOFRX DOFRY DOFRZ 1 0 1 1 1 0 0 0 $ fix bottom rebar node (v=9) *BOUNDARY_SPC_SET $ ID CID DOFX DOFY DOFZ DOFRX DOFRY DOFRZ 2 0 1 1 0 0 0 0 $ fix x,y at top rebar node (v=10) *BOUNDARY_PRESCRIBED_MOTION_SET $ ID DOF VAD LCID SF 1 3 2 111 1.0 $ z-displacement at top node set *DEFINE_CURVE 111, 0, 1., 1., 0., 0. 0.0, 0.0 &Tend, &MaxDisp &Tend2, &MaxDisp

Output:

*DATABASE_NODFOR

&TASCII

*DATABASE_SPCFORC

&TASCII

*DATABASE_BINARY_D3PLOT

&TDplot

*DATABASE_EXTENT_BINARY

$ neiph ... sigflg epsflg ...

5 1 1

4) Run LS-DYNA

Use screen so jobs continue after disconnect:

screen

Then launch (example with 8 cores):

lsdyna i=input.k ncpu=8 > std.out &

Use a modest core count to share cluster resources. Reduce runtime by coarser meshes and/or faster loading, but avoid excessive dynamics.

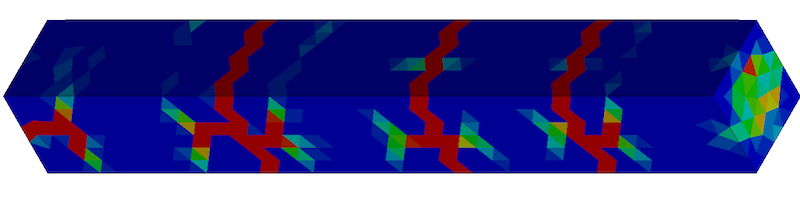

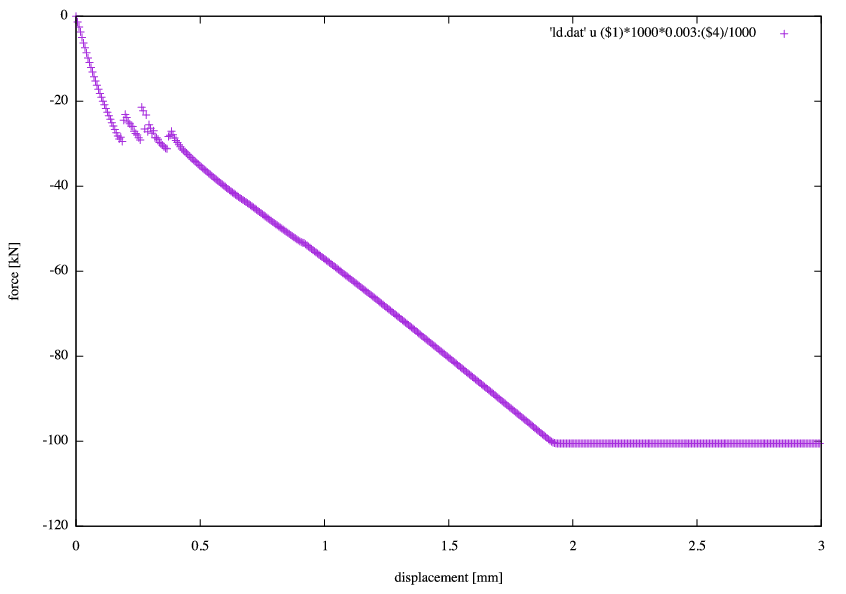

5) Postprocess results

In LS-PrePost, plot maximum principal strain (apply an upper threshold) to visualise cracks. Extract curves with Perl tools:

perl reaction.pl spcforc > output.dat

Single-element example (LS-DYNA)

Coming soon.

Last updated by Peter Grassl